Diagnostics

Diagnostics

Emergency engine shutdown

Limp mode

Check Engine

Unevenly engine idling

Uneven work, especially when idling, is a very common problem with IDE engines. The causes can be divided into three groups: the ignition system, the injection system, and the engine itself. However, before doing anything, it is best to connect the Clip and check that the computer does not see any errors, in particular the camshaft sensor and the flywheel.

First, check the most common cause, i.e. the ignition system. It is best to replace the coil with wires and install new candles. Damage to the coil until it breaks is not visible, similarly with wires, if the wire burns at the connection with the terminal, the spark arises inside the wire, which cannot be seen from the outside.

If the ignition system is operational, check the pressure in the cylinders. Nominally, it should be above 16 bar, a tolerance of up to 10% between the highest and lowest result is possible. In the event of a reduction in compression pressure, it is most often caused by leakage in the exhaust valve seats.

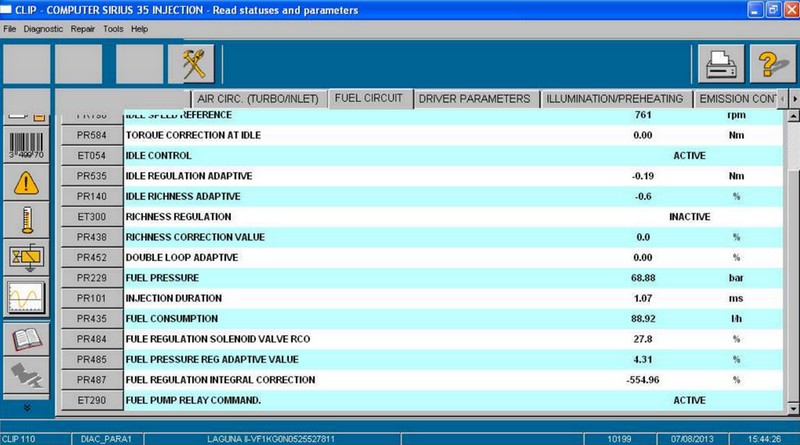

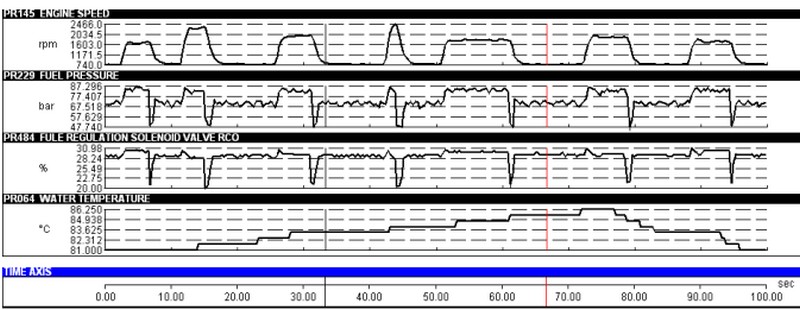

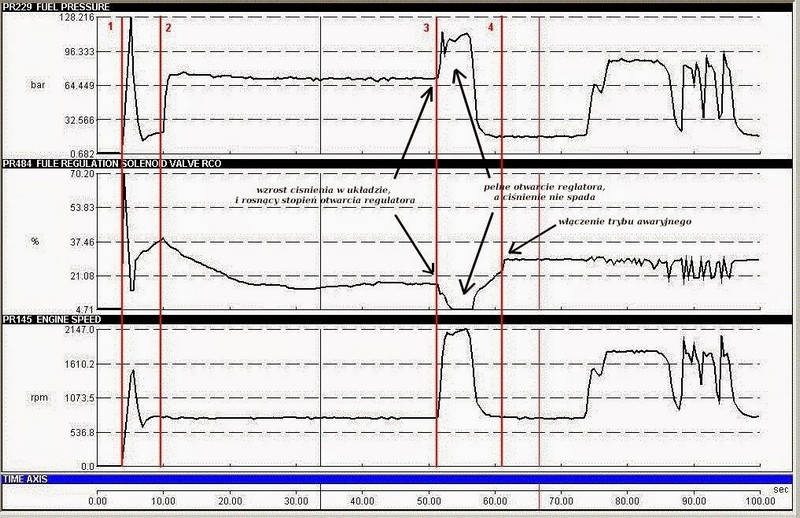

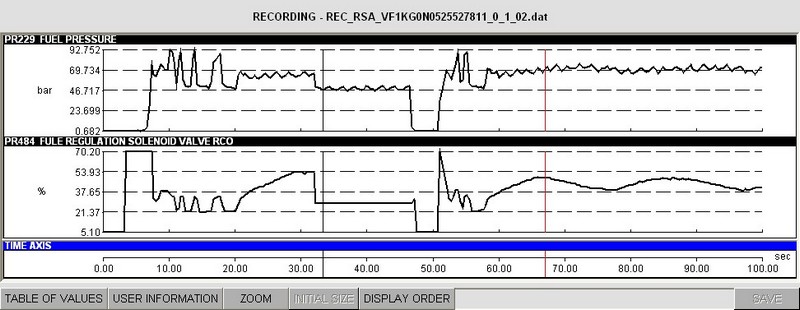

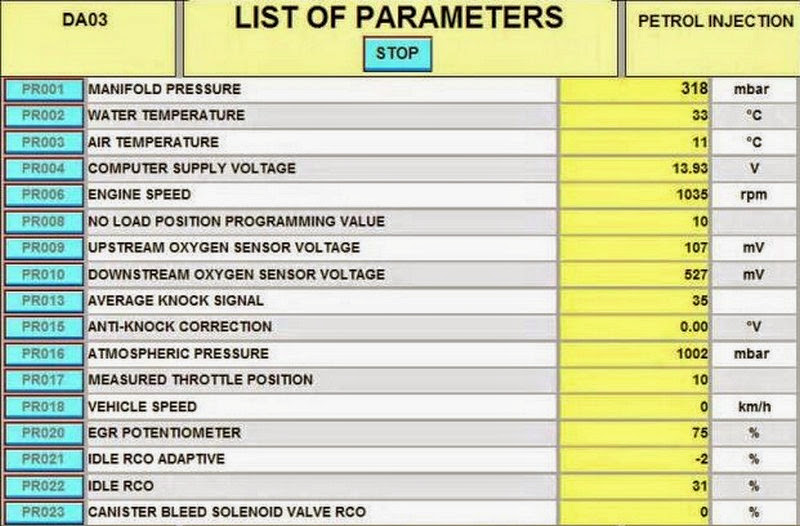

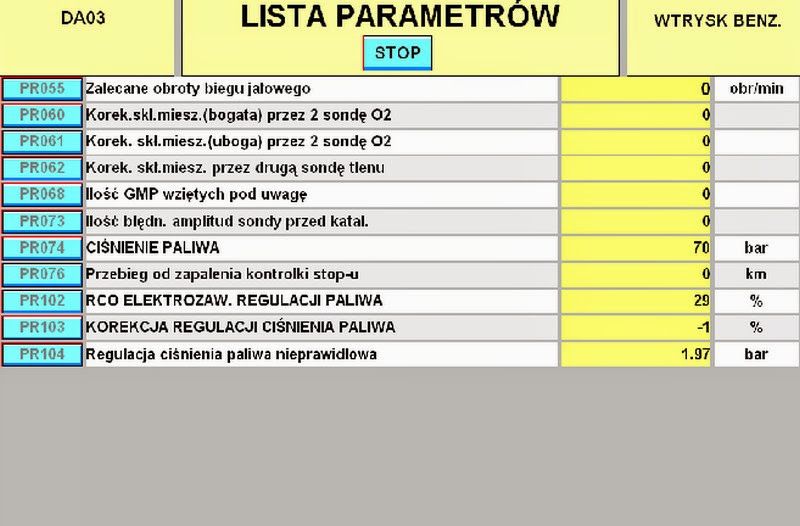

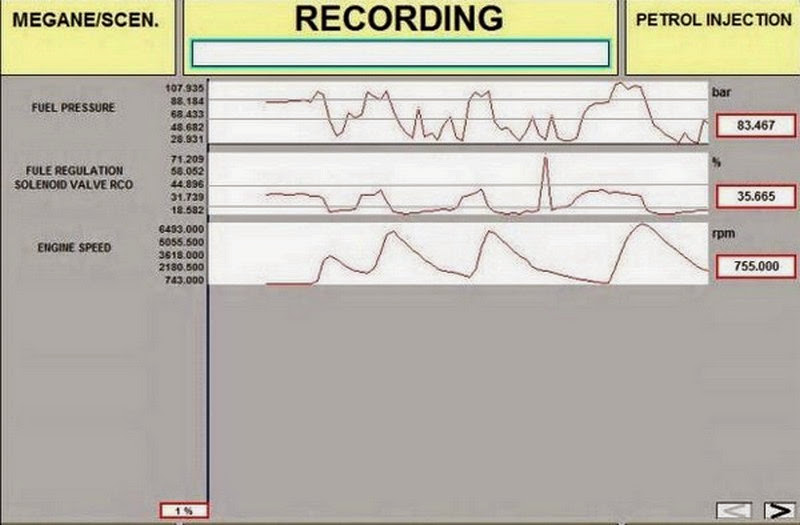

If the compression pressure is correct, the next step is to check the injector, damage is rare but it does happen and you need to take a fuel pressure reading at idle. It happens, for example, when the filter under the pressure regulator is clogged or the regulator itself is damaged, the pressure can fluctuate and within very wide limits (below the Megane mileage of 29-100 bar) and in places of the highest drop of drop, ignitions can fall out. If the problem is still not resolved, check the timing. Very often there is a misalignment of the exhaust valve shaft pulley. Delayed injection can reduce the flexibility of the engine and cause uneven operation.

If the problem persists, also check the condition of the intake pipes. In engines, an early wear of the intake valve seals is a fairly common case, which in turn leads to valve sticking. The degree of sizing is uneven and where it is greatest it can cause a bad mixture composition in a given cylinder.

Difficult start

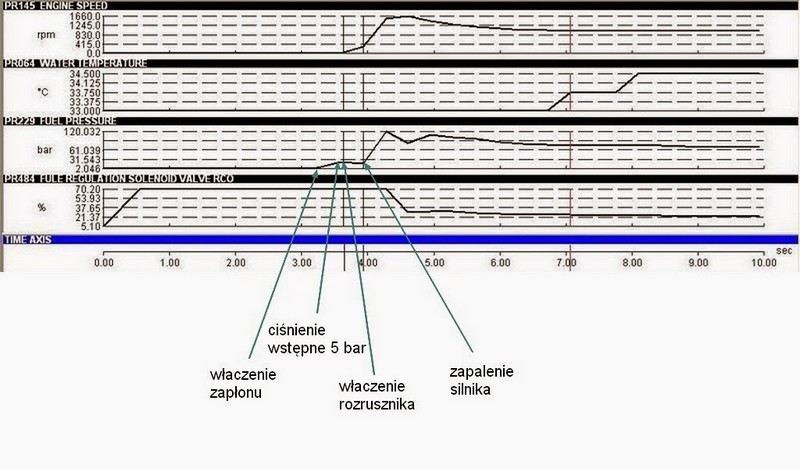

Direct injection engines should ignite within 2 seconds, even in the coldest frost. The main problem here is the time it takes for the injection system to reach the appropriate pressure. During start-up, the pressure regulator is practically closed and the high pressure pump increases the pressure in the system with each revolution. When it reaches the required 20 bar or more, the fuel is atomized sufficiently and the engine starts immediately.

The time to reach the required pressure depends mainly on the efficiency of the high pressure pump, the pressure regulator and the tightness of the system. With an efficient system, this time is less than 2 seconds. The rate of pressure build-up in the system can be measured by including pressure recording before starting the engine.

If the problem is only related to the hot engine, pay attention to the pressure from the forepump and the possibility of gasoline vapors in the high pressure pump when the engine temperature exceeds 70C

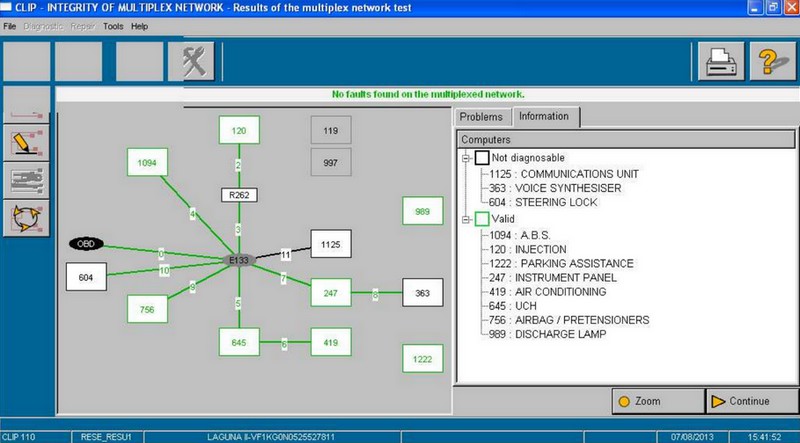

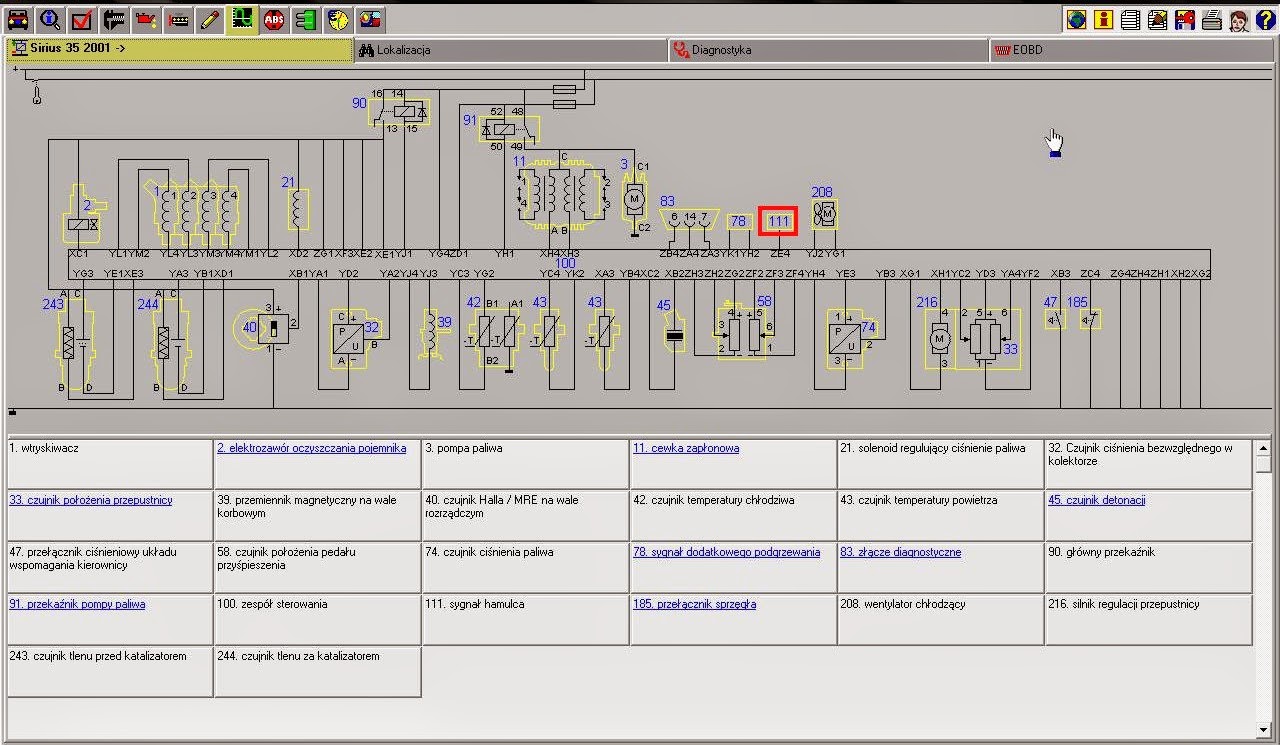

CAN-Clip diagnostics