2.0 idE engine

Renault idE engine

In 1999, Renault developed the first European gasoline engine with electronic direct fuel injection. It is a modernized Mitsubishi GDI unit. In order to improve the engine operating parameters, many modifications were made, such as variable fuel pressure and a greater share of exhaust gases in the leaning of the fuel mixture.

Unfortunately, the pioneering work of Renault engineers ended in a silent failure in 2004. It was mainly caused by difficulties in meeting the increasingly stringent exhaust gas standards and too high failure rate of engines. However, the failure rate did not occur in the engine itself, and mainly related to the engine accessories provided by external suppliers. It was a high pressure pump, a fuel pressure regulator and an EGR valve. When these problems are eliminated, the engine impresses with its performance and low fuel consumption, and despite the passage of many years, its parameters do not differ from much newer designs such as FSI, JTS, D4, CGI.

Currently, in addition to low-cost designs, most gasoline engines are manufactured using the direct injection technology, so probably Renault will also have to apologize to the F5R and re-launch the engine with direct fuel injection.

Unfortunately, most of the failures of the above-mentioned elements resulted in an emergency engine shutdown while driving, which led to the owners' white fever and completely spoiled the opinions about this engine.

In addition, the cost of replacing these elements contributed to this, as Renault would have to replace the entire injection system (pump and complete injection rail) in case of any problems. As if that was not enough, the Renault service procedure did not provide for the replacement of the regulator itself, which was most often damaged, and the rail with the regulator, which required disassembly of the intake manifold and removal of the rail with injectors.

Currently, if the injection system indicator lights up in your Renault IDE or the engine has an emergency shutdown, it is not the end of the world, having a bit of basic knowledge, you can unscrew these elements yourself and regenerate them for a fraction of the amount of new elements.

Engine idE design

The F5R engine was developed by Renault Sport in 2 years at a cost of 15 million euros as the first European gasoline direct injection (IDE) engine.

This technology, successfully used in diesel engines, consists in injecting fuel under high pressure (100 bar) directly into the combustion chamber. The main goal is to improve combustion and increase efficiency. This reduces the suction losses due to the low pressure in the intake manifold, which the piston has to overcome, drawing air into the combustion chamber. The solution adopted to reduce these losses is to increase the pressure in the intake manifold by adding exhaust gas. These two strategies make it possible to reveal the advantages of gasoline direct injection.

In the Japanese Mitsubishi GDI engine, the lean mixture is created by the excess air, which leads to a deviation from the stoichiometric composition of the mixture and causes an increase in emissions, especially of nitrogen oxides. Therefore, Mitsubishi uses additional fuel injection in the vicinity of the spark plug so that the mixture is stoichiometric at the moment of ignition, and then it is burned up with excess air. In the IDE engine, Renault has chosen to create a lean mixture by adding a large amount of exhaust gas that is no longer oxygen-free. The addition of inert gas facilitates the formation of a stoichiometric mixture, and additionally increases the pressure in the manifold, reducing the loss of suction of the engine, which improves the efficiency of the engine.

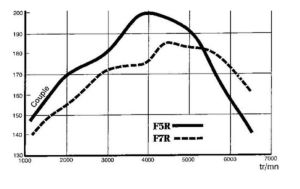

The engine was developed on the basis of the F-series engine family. The F5R IDE is a 16-valve twin overhead camshaft engine developing 103 kW (140bhp) at 5500 rpm with a capacity of 1,998 cc. In the Renault range it replaces the 2.0 16V F7R engine. While the power of the F5R IDE engine is slightly lower than that of the old F7R, the performance is noticeably better due to the more favorable torque curve. The maximum torque is 200 Nm which is high for a 2 liter gasoline engine and with at least 170Nm from 2,000 to 5,650 rpm. The engine is very flexible and snappy when accelerating.

The F5R engine uses 15 to 18% less fuel, or 1.5 l / 100 km less, on the European MVEG test cycle (7.6 vs. 9.1 l / 100 km) compared to the previous 2.0 16V F7R engine. To achieve these results, the F5R engine uses the same engineering features as the 2.0 16V F4R. They have the same cast iron block, cylinder, crankshaft, connecting rods, accessories and exhaust manifold. Instead, it uses roller tappet bearings (50% reduction in valve seat friction), cylindrical camshafts (900 grams weight reduction).

Air intake system

The differences between the two engines are mainly in the cylinder head, combustion chamber and intake manifolds. The engine torque at low revs is optimized by the shape of the intake manifold and the resonator which further improves cylinder filling. The shape of the piston crown has been optimized to increase the mixing of fuel and air for a more even load.

In order to achieve optimal combustion, the F5R engine is equipped with an EGR (exhaust gas recirculation) system that is mounted below the throttle assembly. Under certain conditions, it passes a portion of the exhaust gas to the inlet to obtain a mixture containing fresh air and inert exhaust gases. The EGR also acts as an additional air intake which increases the pressure in the intake manifold and therefore reduces the amount of losses. By optimizing combustion and by adding exhaust gas via EGR, the NOx emissions of nitrogen oxides have been significantly reduced. EGR works when the engine load is between 20 and 50-60%. Outside of this range, the EGR valve is disabled.

Advantages and disadvantages

The engine has many advantages, but also its disadvantages. The advantages include:

- high torque at low revs, which has a positive effect on the dynamics without the need to screw the engine to high revs

- quite low fuel consumption for a two-liter engine, you can easily achieve fuel consumption around 6.5l / 100km on the route, at speeds of up to 120km / h. In the urban cycle, while driving slowly, approx. 8.5 l / 100 km

- With an efficient fuel pressure regulator, the engine is practically failure-free and maintenance-free up to a mileage of approx. 200 thousand km, when it is necessary to replace the high pressure pump.

- Aftermarket IDE lagoons are mostly in perfect condition with low mileage due to a lack of proper knowledge of engine problems.

The disadvantages include:

- no possibility to install LPG, which in Polish conditions can be a serious disadvantage. Such installation is technically possible but not profitable.

- difficulties with car servicing resulting from the lack of knowledge of car repair shops about the drive unit, this also applies to the authorized Renault network

- high prices of injection system parts at authorized Renault services

Next generation of the idE engine, TCe

In 2012, Renault re-launched the direct injection engine. It is a supercharged 1.2-liter 115TCe unit, 115 HP and a torque of 190Nm in the range of 2500-4000 rpm. Many twin units were created on the basis of this engine.

This engine is the successor to the F4M 1.6 16V 110HP engine. In relation to it, many modifications have been introduced, such as direct fuel injection and reduction of internal friction by covering sensitive elements with a DLC (Diamond Like Carbon) coating, variable oil pump efficiency, start & stop system. The engine was built in the currently fashionable downsizing technology, i.e. squeezing out as much power and torque as possible from a small capacity. This is to reduce fuel consumption and CO2 emissions. According to Renault, it was a pioneer in downsizing, introducing in 1980 the F1 engine with a capacity of 1500 and a power of 850HP.

The engine, despite fairly decent parameters on paper, mounted in a fairly heavy Scenic or Megane is a bit disappointing, accelerating to 100 km / h in 11.7 seconds and is rather suitable for smaller models such as Clio. Units from 0.9 Tce (3 cylinders 90HP) to 1.2 TCe were also produced. Work is underway on larger capacity units. It should be noted that currently the units marked as TCe also have indirect injection, which is a bit confusing.